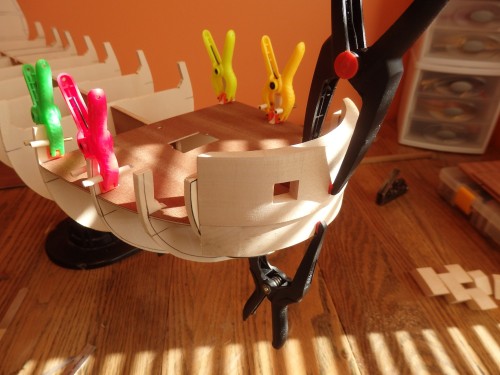

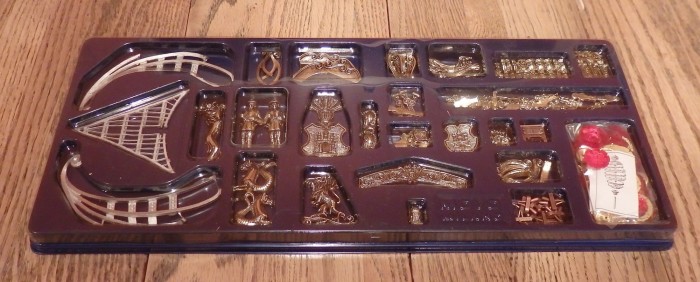

So begins the arduous process of planking the hull. The first plank, or Gunwale, is the uppermost plank of the ships hull. It will define the “run of the ship” or the curvature of hull from bow to stern. It is important to note that the Gunwale does not follow deck, but instead tends to curve down midship, and then up again as the plank approaches the stern of the vessel, as shown below.

Since several of the lower decks need to be fitted out on this model, the plank I started with in the above photo probably isn’t technically the Gunwale plank, because there will be others above it as we add the remaining gun decks. However, its importance is significant in defining the curvature of the planks from bow to stern.

At this point, it is probably a good idea to say something about the method employed for fastening the planks to the bulkheads. I used yellow carpenters glue and a curved syringe (see one of the later photos). It is important to not only apply glue to the contact points on the bulkheads but also along the entire edge of the previously glued plank. This, in my opinion, provides much needed additional support to the planking in general, especially if you have not opted to use any fillers between the bulkheads for the purposes of providing curvature and additional gluing surface.

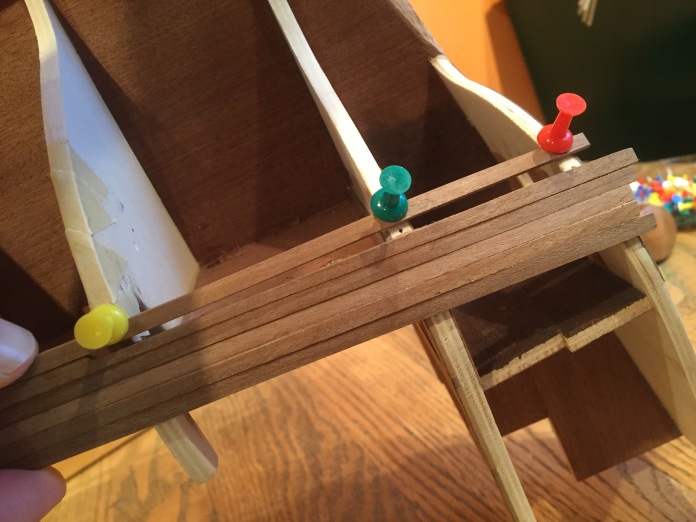

You will also notice in my photos that I am using plastic headed thumbtacks to hold the planks in place while the glue dries. This turns out to be a very effective means of clamping planks to their respective bulkheads. There are a variety of planking clamping tools out there, and I have not found any of them to be nearly as effective as this approach.

One catch is that you should probably drill small pilot holes to accommodate each pin on each bulkhead prior to gluing your plank in place. I used a cordless Dremel to drill these holes very rapidly. Make sure the pilot holes are sufficiently small such that the pins will be very secure when pushing them in after gluing. The pilot hole is drilled immediately next to the plank and the head of the pin will then hold in the plank while it dries without producing any unsightly nail holes that need to be filled later. Using disposable pins such as these provides the additional benefit that the pins themselves can be bent as you place them into the pilot holes to accommodate hull curvature.

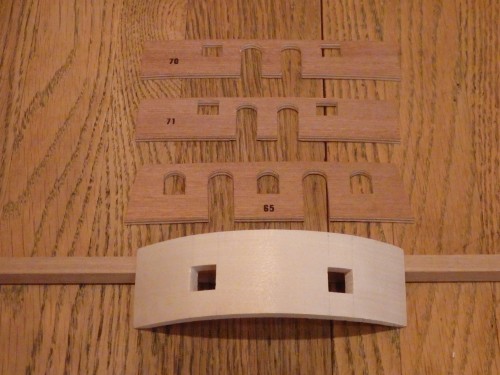

For the bow ends of the planks, I created a bending jig similar to that shown in the above photo. Since this particular ship does not contain extreme curvature at the bow, nor at the stern (in fact no pre-bending is required at the stern), simply soaking the planks in boiling water for a few minutes, and then clamping them to the above jig and allowing them to dry will produce the needed curvature without the use of a planking iron.

All I did to produce the bending jig was use a french curve to approximately match the curvature of the hull on a piece of scrap wood. Then, sink several screws at regular intervals along this curve, preferably screws that aren’t threaded near the tops. Finally, to prevent the screws from digging into the planks, wrap each ones smooth top in electrical tape to provide a padded surface upon which to clamp the planks as they dry. I was able to bend approximately 6 planks at once using the above jig, 3 side by side at 2 layers deep. Using the pre-bending jig will easily allow the planks to bend along the curvature of the box as shown.

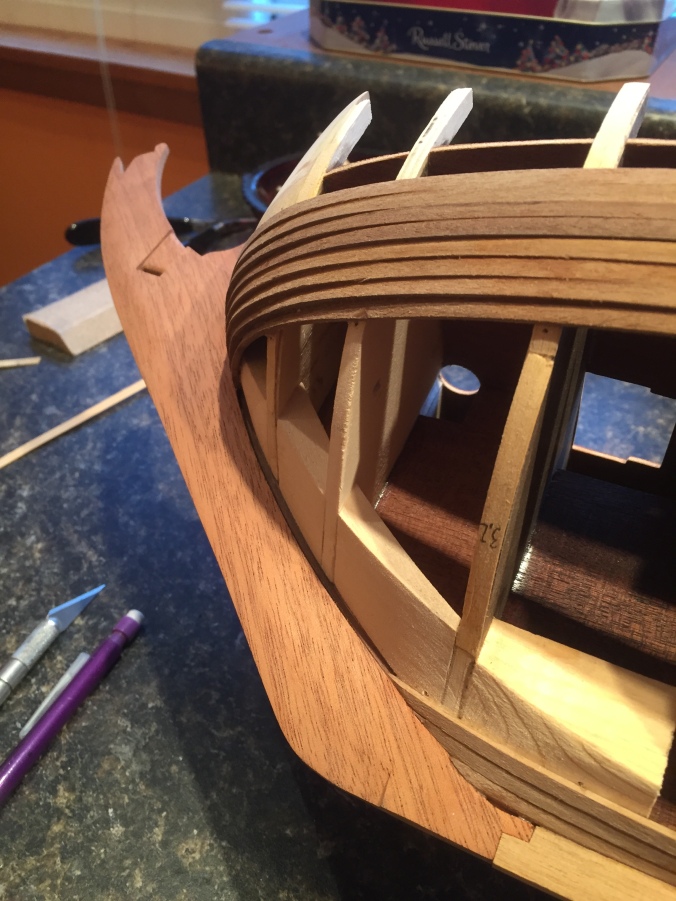

You will notice several things about the planking at the bow as shown in this photo.

First, note the fillers that I applied to some of the bulkheads in order to true them up prior to planking. This can be done by layering and gluing thin wood scraps to the bulkheads at any locations that tend to run low. Sand the fillers to blends them to the other bulkheads and to the bulkhead to which they are fastened to finish the job. Of course, any bulkheads that tend to run high can simply be sanded down until the high spot is removed.

Second, note the rabbit between the stem and the bow that provides a nice notch for fitting the plank during the gluing process. I always begin a plank by fitting it into this rabbit and gluing from bow to stern, as the planks can be left overhanging the stern for this particular ship.

Thirdly, and possibly most important is that the width of the planks at the bow must be tapered. For this particular ship, in fact, they need to be tapered to about half their original width at the bow. There is also a span slightly forward of the stern where the planks need to be tapered as well. The tapering of each plank along the entire length of the hull can be determined by taking strips of paper, or thin wood stock, and measuring the curved length of several bulkheads along the length of the hull. The length to be measured should be the distance between the keel, and the Gunwale plank about every 2 to 3 bulkheads, depending on the degree of change you are trying to capture. Once you have these lengths, take the longest length that occurs mid-ship, and divide it by the width of your planking material. This will give you the number of planks you will need to cover the span. Then, at bulkheads where the length is less than this maximum, divide each length by this number of planks you determined in the previous step to determine the approximate width that each plank needs to be at each bulkhead. You will then find you have a rough template for sanding off the width of the planks. Note that the distance at the stern will actually be greater than at mid-ship, requiring the addition of “stealers”, or additional short planks to make up for this additional distance at the stern.

I found that a belt sander works very nicely for sanding a continuous curvature into each plank. In fact, before I even pre-bend my planks using the jig described earlier, I will taper the planks to their necessary width at the bow end by applying a stack of them to a running belt sander, and applying pressure to the stack using a scrap piece of wood. This gets you the bulk of the tapering for the bow, prior to even bending the plank. Then once the planks are ready to be placed, I will fine-tune their curvature by smoothly running the edge of the plank along the curved edge of the belt sander. You should also taper the edges of each plank inward the tiniest bit along their entire length, as this will guarantee a tight fit against each other on the hull.

Once a few planks had been fastened along the Gunwale plank, I moved to the keel and placed the Garboard plank along with a few others alongside it. There isn’t too much special to say about the Garboard plank except that it will possibly require a little additional sanding in order to get its edge to fit in the rabbit between the keel and the bulkheads.

You will likely find that “stealers” will be needed at the stern as shown in the photo above. Stealers should typically be tapered to about 2/3 their width at the bow end, and they should maintain their full width at the stern end. I typically notch out the preceding plank 2 to 3 bulkheads in from the stern, prior to even gluing this plank to the hull. Then, I will add the tapered stealer, and the next plank can again be notched to accommodate the end of the stealer. Throughout all of this, avoid removing any width at the stern-most end of the planks because recall that the goal here is to cover a larger distance by adding the stealer in the first place.

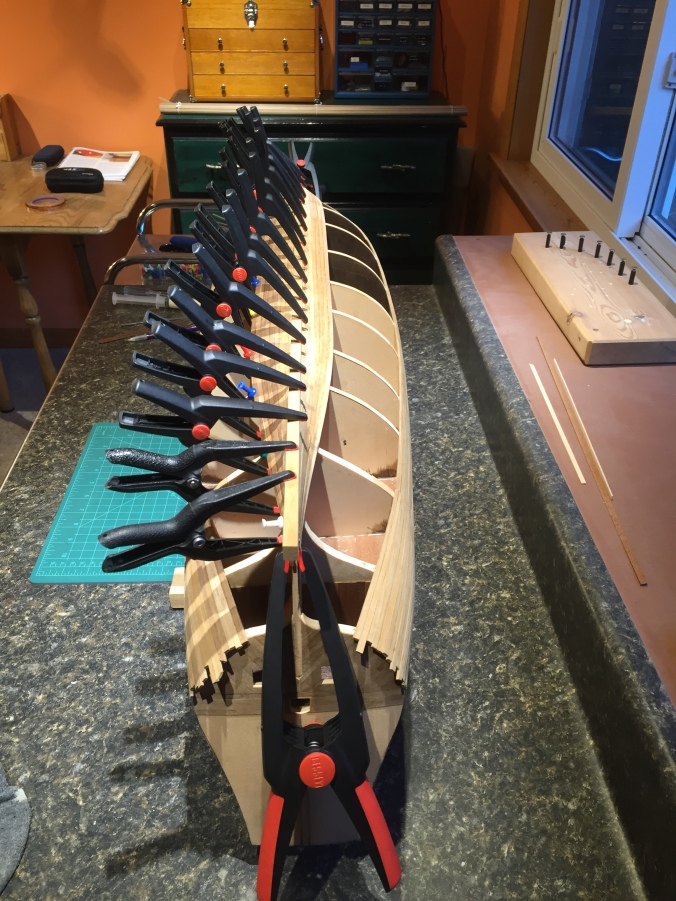

In combination with the push pins, a good set of clamps is a must for the task of planking. As you can see in the above photo, I tend to place one clamp at the mid-point between each bulkhead and gluing a plank in place. This ensures a tight fit against the plank immediately preceding the one being glued. Larger clamps can be used for uncooperative plank ends such as at the stern where a pretty decent twist is required.

Eventually, your “strake” or group of planks will become too wide for your clamps. When this happens, just skip a plank to create a gap. Even better, this plank that you skip – shape it ahead of time and use it to glue the first plank of the next strake. You can ensure that it doesn’t accidentally become fastened to the bulkheads by laying little strips of wax paper between it, and the bulkheads and first plank of the next strake. Then when the first plank of the next strake is dried in place, this plank can be removed and you have a perfect gap for applying your clamps as shown in the photo. Just be sure and mark the planks that you removed so you have it for later.

Several strakes can be completed in just this manner, leaving you with only a couple gaps to fill in later. When it is finally time to place these final planks, you will find that your pins are useless under this scenario. So, take several plank scraps and sand them down to a very fine point that their end. Then, do any final shaping to your gap-filler plank so that it fits in the space you created previously. When it comes time to glue it in place, use the sharpened scraps as wedges to secure the plank in place while it dries (see photo below).

When you are though, you may find that time and humidity, or even a few mistakes along the way, have resulted in some gaps between some of your planks. To remedy this, I would recommend sanding some plank scraps down to very thin width and inserting them into these gaps to fill them as opposed to using wood fillers. This will result in relatively invisible repairs to any imperfections that remain. Once you sand down the hull, you can repeat this process for any additional gaps that may appear during this process.

I’m fairly satisfied with the end result of this technique, and I look forward to providing updates in the future as I move toward fitting out the lower gun decks.